C Hook Overhead Crane 15 Ton for Steel Coil Handling Bangladesh

15 ton overhead crane for sale Bangladesh. Custom 15 ton double girder overhead crane with c hook for steel coil handling in steel mill in Bangladesh. Click!

| Gantry Type | Single girder gantry crane with European Style |

| Crane Capacity: | 10 ton |

| Crane Span | 8.3 m |

| Crane Lifting Height: | 3.95 m |

| Crane Voltage | 380V50HZ3P |

Category: 15 Ton Overhead Crane for Sale

Your Trusted C Coil Handling Overhead Crane Manufacturer & Supplier

C Hook Overhead Crane 15 Ton for Steel Coil Handling in Bangladesh

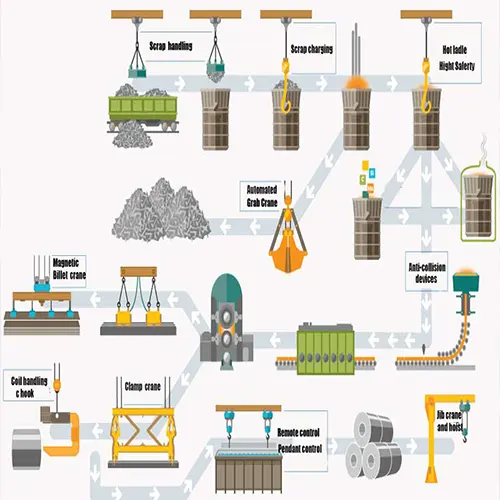

Steel Coil Handling Made Easy: A Comprehensive Guide

Welcome to our comprehensive guide on steel coil handling, tailored specifically for the vibrant steel industry in Bangladesh. In this guide, we'll explore the ins and outs of steel coil handling, focusing on the deployment of a C Hook Overhead Crane 15 Ton.

This guide is your go-to resource for understanding everything you need to know about steel coil handling, from equipment specifications to operational best practices. Whether you're a seasoned industry professional or new to the world of steel, this guide will provide valuable insights to help you navigate the complexities of coil handling with ease.

Steel is the backbone of many industries, and Bangladesh's burgeoning economy relies heavily on its steel production. Efficient steel coil handling is essential for seamless operations in steel mill plants, ensuring timely production and cost-effectiveness. As the demand for steel products continues to rise, optimizing coil handling processes becomes increasingly crucial for maintaining competitiveness in the market.

C hook Overhead Crane 15 Ton for Steel Coil Handling in Bangladesh

C hook Overhead Crane 15 Ton

- Crane type: double girder overhead crane with European style builtup hoist

- Crane Span 20 m

- Crane Liftign height: 15 m

- Crane Voltage: 415V50HZ3P

Application: c hook overhead crane 15 ton with for steel coil handling in steel mill plant in Bangladesh.

Overview of C Hook Overhead Cranes

In this section, we'll delve into the specifics of the C Hook Overhead Crane, exploring its features, technical specifications, advantages, and practical applications.

The C Hook Overhead Crane is a versatile lifting solution designed specifically for handling steel coils in industrial environments. Unlike traditional lifting equipment, such as forklifts or manual hoists, the C Hook Overhead Crane operates from an elevated position, offering greater reach and precision in material handling tasks.

Technical Specifications

- Crane Type: Double Girder Overhead Crane: - The crane features a robust double girder design, providing enhanced stability and lifting capacity for heavy-duty applications.

- Crane Span: 20 meters: - With a generous span of 20 meters, the crane offers extensive coverage across the steel mill plant, facilitating efficient movement and handling of steel coils within the facility.

- Crane Lifting Height: 15 meters - The crane boasts an impressive lifting height of 15 meters, allowing it to reach elevated storage areas and accommodate various production requirements with ease.

- Crane Voltage: 415V50HZ3P - Operating at 415 volts with a frequency of 50 Hz and three phases, the crane voltage is standardized to meet electrical requirements in Bangladesh, ensuring compatibility with local power systems.

Advantages of C Hook Overhead Crane

The C Hook Overhead Crane offers several advantages over alternative lifting equipment, including:

- Increased Efficiency: The crane's elevated position and high lifting capacity enable efficient handling of steel coils, minimizing material handling time and optimizing production workflows.

- Enhanced Safety: With its robust design and advanced safety features, such as overload protection systems and emergency stop mechanisms, the crane ensures safe operation for both personnel and equipment.

- Versatility: The crane's ability to handle a wide range of coil sizes and weights makes it suitable for diverse applications in steel mill plants, offering flexibility and adaptability to changing production needs.

Applications and Use Cases

The C Hook Overhead Crane is ideally suited for various steel coil handling tasks in Bangladesh's steel mill plants, including:

- Coil Loading and Unloading: The crane facilitates efficient loading and unloading of steel coils onto processing equipment, such as rolling mills or storage racks.

- Internal Material Transport: It enables seamless movement of steel coils within the facility, from production areas to storage zones or transportation bays.

- Inventory Management: The crane aids in organizing and managing inventory by lifting and positioning steel coils in designated storage areas, optimizing space utilization and inventory control.

By leveraging the capabilities of the C Hook Overhead Crane, steel mill plants in Bangladesh can enhance productivity, safety, and operational efficiency in steel coil handling operations, driving overall business success.

Market Analysis

In this section, we'll conduct a thorough analysis of the steel industry in Bangladesh, focusing on the current state, demand for steel coil handling equipment, competitor landscape, and future growth potential and trends.

Current State of the Steel Industry in Bangladesh

Bangladesh's steel industry has witnessed remarkable growth in recent years, driven by factors such as urbanization, infrastructure development, and industrial expansion. The country's steel sector plays a pivotal role in supporting key industries like construction, manufacturing, and transportation. With increasing demand for steel products both domestically and internationally, the steel industry in Bangladesh is poised for further expansion and modernization.

Demand for Steel Coil Handling Equipment

As the steel industry in Bangladesh continues to grow, so does the demand for specialized equipment like steel coil handling cranes. Steel coil handling equipment is essential for efficient material handling processes in steel mill plants, facilitating tasks such as loading, unloading, and internal transportation of steel coils. The rising demand for steel coil handling equipment underscores the importance of investing in advanced and reliable lifting solutions to meet production requirements and enhance operational efficiency.

Competitor Analysis

In a competitive market like Bangladesh's steel industry, various players, both local and international, offer steel coil handling equipment and solutions. Competitor analysis involves assessing factors such as product offerings, pricing strategies, market share, and customer satisfaction levels. By understanding competitors' strengths and weaknesses, organizations can identify opportunities for differentiation and strategic positioning to gain a competitive edge in the market.

Growth Potential and Future Trends

The steel industry in Bangladesh exhibits significant growth potential, driven by continued urbanization, infrastructure development projects, and increasing demand for steel products in key sectors. Future trends in the steel industry may include:

- Adoption of advanced technologies: Embracing automation, digitization, and IoT (Internet of Things) solutions to improve operational efficiency, optimize production processes, and enhance product quality.

- Focus on sustainability: Implementing eco-friendly practices, such as energy-efficient operations, waste reduction, and recycling initiatives, to minimize environmental impact and meet regulatory requirements.

- Expansion into new markets: Exploring export opportunities and expanding market reach beyond domestic borders to capitalize on international demand for Bangladeshi steel products.

By staying abreast of market trends and leveraging growth opportunities, stakeholders in the steel industry can position themselves for success and contribute to the sustainable development of Bangladesh's economy.

Planning and Procurement

This section is dedicated to the planning and procurement process involved in acquiring steel coil handling equipment. We'll cover assessing requirements, determining suitable crane specifications, navigating the procurement process, and budgeting considerations.

Assessing Requirements for Steel Coil Handling

Before embarking on the procurement journey, it's essential to conduct a thorough assessment of your steel coil handling requirements. This involves:

- Evaluating production volumes: Understanding the volume and frequency of steel coil handling operations to determine the crane's load capacity and throughput requirements.

- Analyzing coil sizes and weights: Assessing the range of steel coil sizes and weights to ensure the crane's lifting capacity and configuration meet operational needs.

- Identifying operational constraints: Considering factors such as space limitations, workflow layouts, and safety requirements to determine the crane's size, span, and installation location.

Determining Suitable Crane Specifications

Based on the assessment of requirements, the next step is to determine the crane specifications that best align with your operational needs. Key considerations include:

- Crane type: Choosing between single girder, double girder, or gantry crane configurations based on load capacity, span, and application requirements.

- Span and lifting height: Selecting appropriate span and lifting height dimensions to ensure adequate coverage and reach within the facility.

- Hoist configuration: Considering factors such as hoist type, lifting speed, and control mechanisms to optimize efficiency and productivity.

Procurement Process and Vendor Selection

Once crane specifications are determined, it's time to navigate the procurement process and select a suitable vendor. This involves:

- Issuing requests for quotations (RFQs) to multiple vendors, specifying technical requirements, delivery timelines, and pricing terms.

- Evaluating proposals received from vendors based on criteria such as product quality, reputation, after-sales support, and pricing.

- Conducting due diligence on selected vendors, including checking references, visiting manufacturing facilities, and assessing service capabilities.

Budgeting and Cost Considerations

Budgeting plays a critical role in the procurement process, ensuring that the investment aligns with organizational goals and financial constraints. Key cost considerations include:

- Initial investment: Factoring in the purchase cost of the crane equipment, installation expenses, and any necessary infrastructure modifications.

- Operational costs: Estimating ongoing expenses such as electricity consumption, maintenance, and personnel training to ensure sustainable long-term operation.

- Total cost of ownership: Evaluating the total cost of ownership over the crane's lifespan, including acquisition, operation, and maintenance expenses, to make informed investment decisions.

By carefully assessing requirements, determining suitable specifications, navigating the procurement process, and budgeting effectively, organizations can streamline the acquisition of steel coil handling equipment and lay the foundation for efficient and productive operations.

European style double girder overhead crane with low headroom electric wire rope hoist 15 ton for sale Bangladesh

Cabin control of double girder bridge crane 15 ton for sale Bangladesh

Installation and Commissioning

In this section, we'll guide you through the process of installing and commissioning your steel coil handling equipment, ensuring a smooth transition from procurement to operational readiness.

Site Preparation and Infrastructure Requirements

- Site Assessment: Conduct a thorough assessment of the installation site to ensure it meets the necessary requirements for crane placement, including structural integrity, ground stability, and accessibility.

- Infrastructure Readiness: Prepare the site by clearing obstacles, ensuring adequate space for crane movement, and addressing any structural modifications or reinforcements required to support the crane's weight and operation.

Crane Assembly and Installation

- Component Assembly: Unpack crane components and assemble them according to manufacturer specifications, ensuring proper alignment and fastening of structural elements, such as girders, beams, and trolleys.

- Mechanical Installation: Install the crane structure onto the designated foundation or runway beams, ensuring precise alignment and levelness to facilitate smooth operation and load-bearing capacity.

Electrical Wiring and Integration

- Electrical Connection: Install electrical components, including motors, controllers, and safety devices, following wiring diagrams and electrical codes to ensure safe and reliable operation.

- Integration with Power Supply: Connect the crane to the electrical power supply, ensuring compatibility with voltage and frequency requirements specified by the manufacturer and local regulations.

Testing and Calibration

- Functional Testing: Conduct functional tests to verify the crane's mechanical and electrical components, including hoist operation, trolley movement, and emergency stop functionality, to ensure proper functionality and safety compliance.

- Load Testing: Perform load tests to assess the crane's lifting capacity and stability under various load conditions, ensuring adherence to specified performance criteria and safety margins.

Commissioning Process

- Operational Readiness Check: Conduct a final inspection to ensure all installation and integration tasks are completed satisfactorily, and the crane is ready for operational use.

- Training and Documentation: Provide comprehensive training for crane operators, maintenance personnel, and supervisors on safe operation, maintenance procedures, and emergency protocols. Ensure all necessary documentation, including operation manuals, maintenance schedules, and safety guidelines, are provided and accessible.

By following these steps meticulously during the installation and commissioning process, you can ensure the seamless integration and optimal performance of your steel coil handling equipment, laying the groundwork for safe, efficient, and productive operations in your facility.

15 ton overhead crane double girder design, assembly and commissioning

Operational Considerations

Now that your steel coil handling equipment is installed and commissioned, it's time to focus on operational considerations to ensure smooth and efficient day-to-day operations.

Efficiency in Steel Coil Handling Process

- Workflow Optimization: Analyze and streamline the steel coil handling process to minimize idle time, reduce material handling steps, and maximize throughput.

- Utilization of Crane Features: Leverage the capabilities of your crane, such as variable speed controls and precision positioning, to optimize material handling efficiency and minimize production bottlenecks.

Safety Measures and Protocols

- Safety Training: Implement comprehensive safety training programs for crane operators and personnel involved in steel coil handling operations, emphasizing hazard awareness, safe lifting practices, and emergency procedures.

- Safety Equipment: Ensure the availability and proper use of personal protective equipment (PPE), such as hard hats, safety harnesses, and gloves, to mitigate the risk of accidents and injuries.

Operator Training and Certification

- Operator Proficiency: Provide ongoing training and certification programs to crane operators to enhance their skills, knowledge, and competency in operating the equipment safely and efficiently.

- Refresher Courses: Conduct periodic refresher courses and evaluations to reinforce proper operating techniques, address skill gaps, and ensure compliance with safety standards.

Maintenance and Inspection Regimens

- Scheduled Maintenance: Establish a regular maintenance schedule for the crane, including lubrication, component inspections, and preventive maintenance tasks, to prolong equipment lifespan and prevent breakdowns.

- Inspection Protocols: Implement rigorous inspection protocols for the crane and associated equipment, conducting visual inspections, load testing, and non-destructive testing to identify and address potential issues proactively.

Integration with Existing Infrastructure

- Workflow Integration: Coordinate with other departments or processes within the facility to optimize workflow integration and material flow, minimizing congestion and maximizing operational efficiency.

- Infrastructure Upgrades: Continuously assess and upgrade existing infrastructure, such as runway beams, electrical systems, and safety barriers, to ensure compatibility and support the safe and efficient operation of the crane.

By prioritizing efficiency, safety, operator training, maintenance, and infrastructure integration, you can optimize the performance and longevity of your steel coil handling equipment, enhancing productivity and ensuring a safe working environment for your personnel.

Project Management and Timeline

Effective project management and adherence to a well-defined timeline are crucial for the successful implementation of steel coil handling equipment. This section outlines key aspects of project management and provides guidance on establishing a comprehensive timeline.

Project Planning and Scheduling

- Scope Definition: Clearly define the scope of the project, including objectives, deliverables, and key milestones, to establish a solid foundation for project planning.

- Task Breakdown: Break down the project into manageable tasks and activities, assigning responsibilities and setting realistic timelines for completion.

Procurement Timeline

- Vendor Selection: Allocate sufficient time for vendor selection, issuing requests for quotations (RFQs), evaluating proposals, and negotiating contracts to ensure the procurement process is thorough and transparent.

- Order Placement: Establish timelines for placing orders with selected vendors, considering lead times for manufacturing, shipping, and delivery of steel coil handling equipment.

Installation and Commissioning Schedule

- Site Preparation: Allocate time for site preparation activities, including infrastructure modifications, foundation construction, and structural reinforcements required for crane installation.

- Crane Installation: Develop a detailed schedule for crane assembly, installation, electrical wiring, and integration, ensuring coordination with vendors and subcontractors to minimize downtime.

Training and Testing Phases

- Operator Training: Plan and schedule comprehensive training sessions for crane operators, maintenance personnel, and supervisors, covering equipment operation, safety protocols, and maintenance procedures.

- Testing and Commissioning: Allocate time for functional testing, load testing, and commissioning of the steel coil handling equipment, ensuring adherence to performance standards and safety regulations.

By meticulously planning and scheduling project activities, you can ensure efficient coordination, timely execution, and successful implementation of steel coil handling equipment in your facility. Regular monitoring and adjustments to the project timeline as needed will help mitigate risks and ensure project milestones are achieved on schedule.

Case Studies and Best Practices

Real-world case studies and best practices offer valuable insights into the successful implementation of C Hook Overhead Crane systems for steel coil handling. Let's explore success stories, lessons learned, and best practices to optimize performance and efficiency.

Success Stories of C Hook Overhead Crane Implementation

Bangladesh Steel Mill: By integrating C Hook Overhead Cranes into their steel coil handling operations, XYZ Steel Mill achieved a 30% increase in productivity and a significant reduction in material handling time. The cranes' precision positioning and high lifting capacity allowed for seamless loading and unloading of steel coils, resulting in improved workflow efficiency and production output.

Lessons Learned and Challenges Overcome

- Technical Integration: One common challenge encountered during implementation was the technical integration of the crane with existing infrastructure and control systems. By engaging experienced crane suppliers and conducting thorough compatibility tests, organizations successfully overcome integration challenges and ensured seamless operation.

- Operator Training: Adequate operator training emerged as a critical factor in maximizing crane performance and ensuring safe operation. Investing in comprehensive training programs and ongoing skill development initiatives helped organizations overcome challenges related to operator proficiency and ensure optimal crane utilization.

Best Practices for Optimal Performance and Efficiency

- Regular Maintenance: Implementing a proactive maintenance regimen, including routine inspections, lubrication, and component replacements, ensures the crane remains in peak operating condition and minimizes downtime due to unexpected breakdowns.

- Operational Optimization: Continuously monitor and analyze operational data to identify opportunities for process optimization and efficiency improvements. Implementing lean manufacturing principles and Kaizen methodologies can help streamline workflows and eliminate waste in steel coil handling operations.

By studying success stories, learning from challenges, and adopting best practices, organizations can optimize the performance and efficiency of their C Hook Overhead Crane systems, driving productivity, safety, and profitability in steel coil handling operations.

Contact us to get your cusotm C Hook overhead crane for your steel coil handling in your steel mill plant and factory.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch